Rising damp

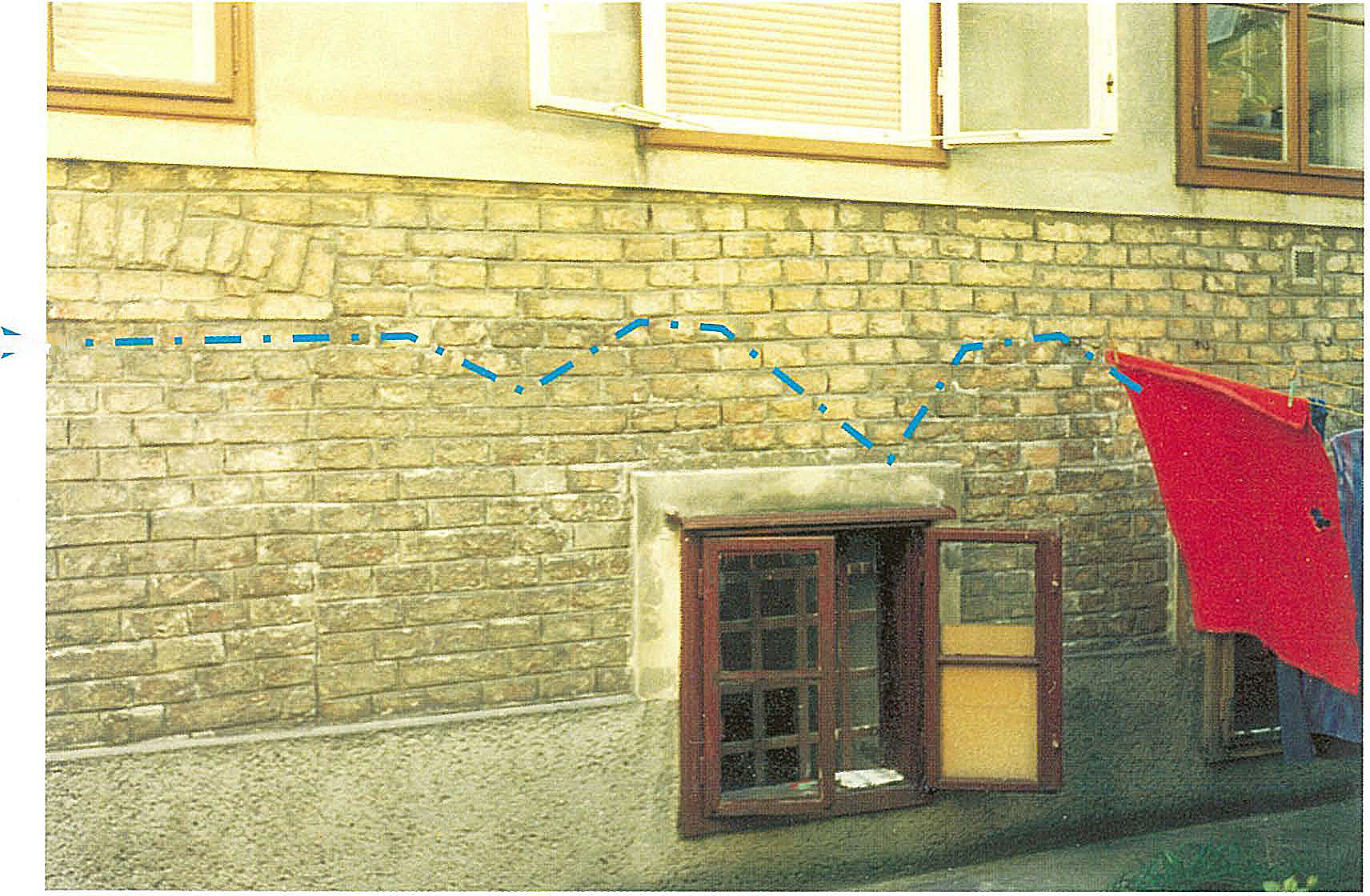

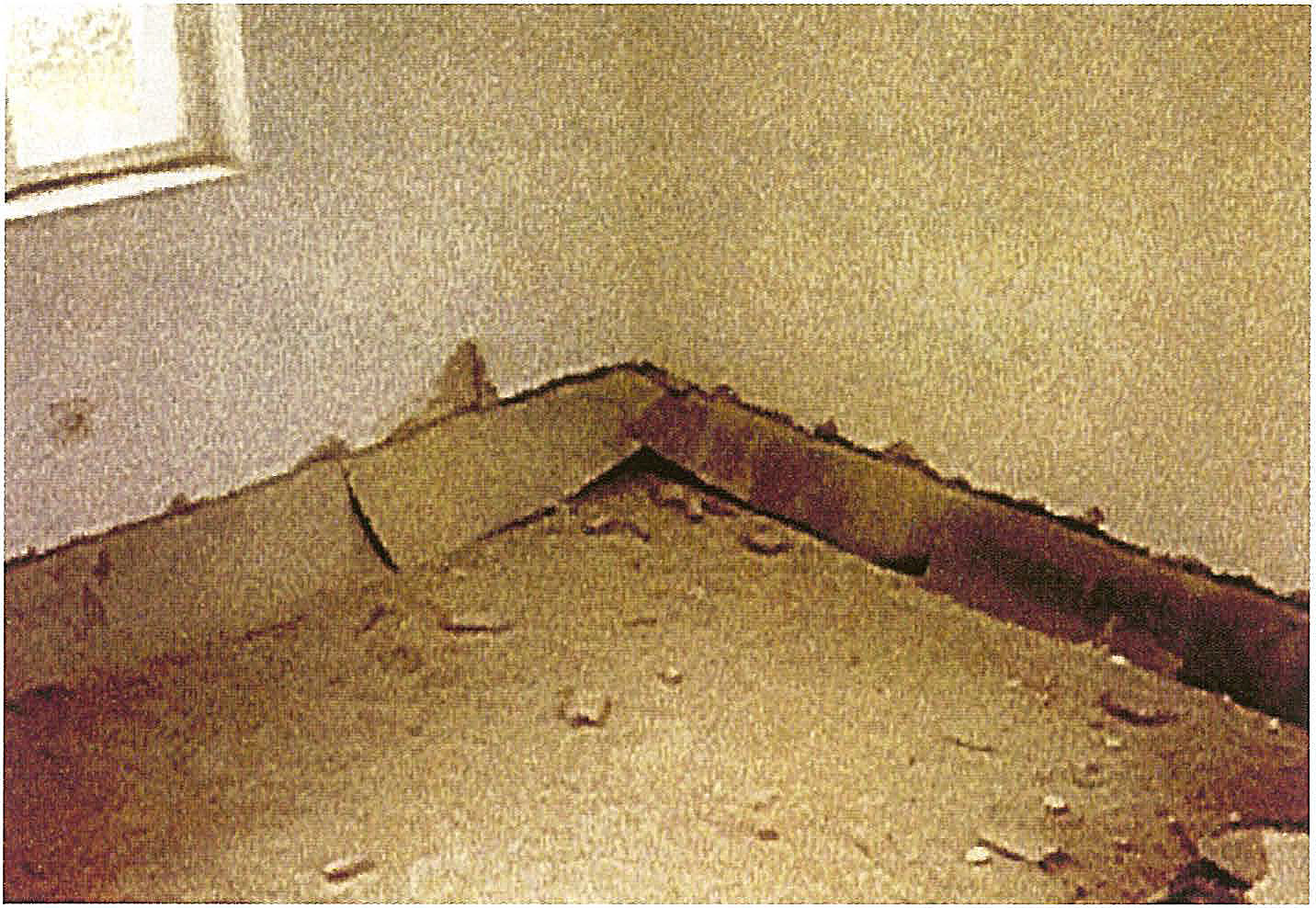

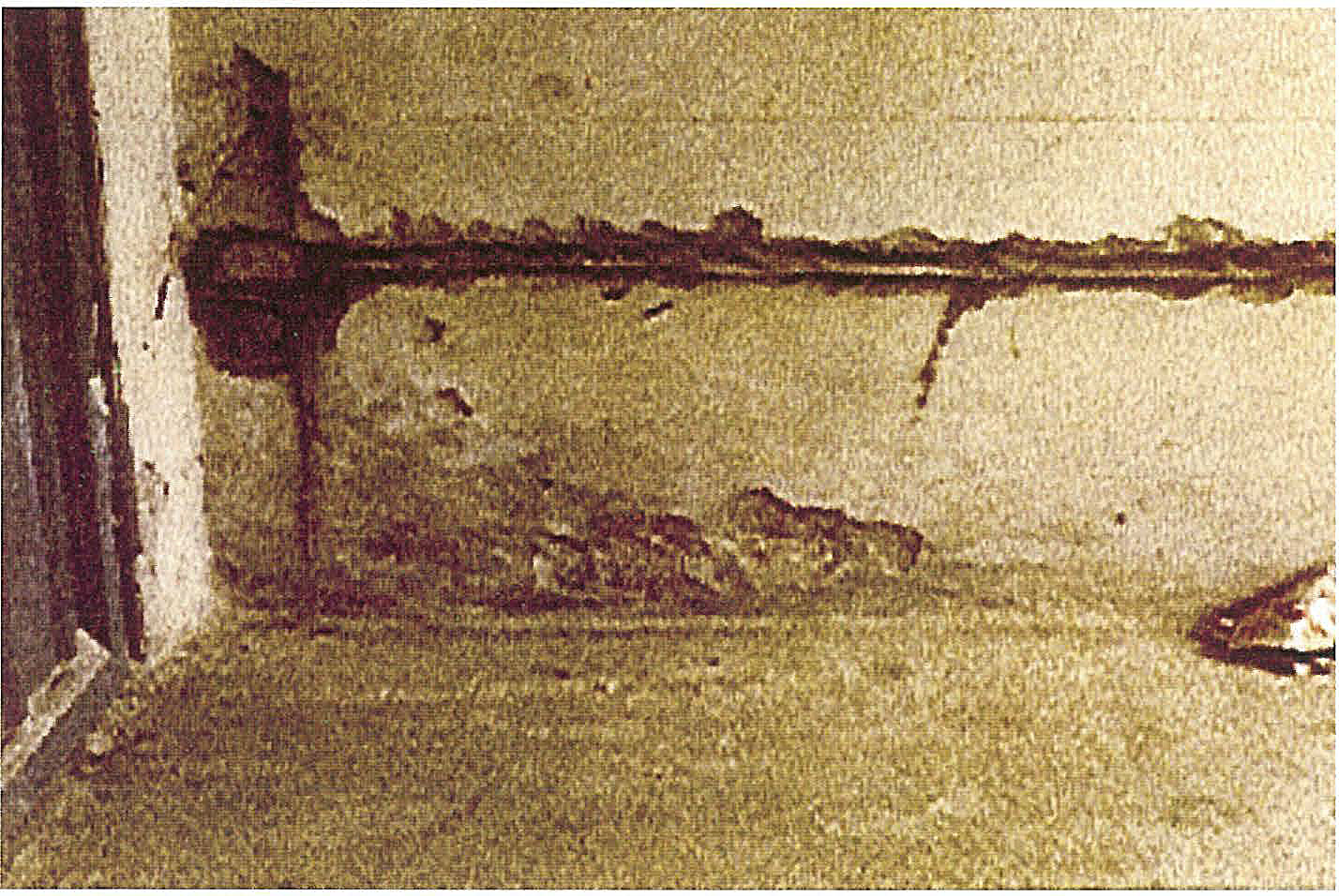

Rising damp in masonry is a phenomenon that is due to the capillarity of building materials. Every mineral building material has capillarity, so also all natural stones, concrete, bricks, etc. If the building material itself has little or no capillarity (e.g. granite), rising masonry moisture finds an easily accessible way upwards via mortar joints. In the base and foundation area or in the lower area of walls, rising water causes consequential damage that creates a very unpleasant living climate. Salts transported from the soil cause the plaster to flake off, as the salts crystallise on the surface after the water has evaporated. The water-filled capillaries lead to frost damage and peeling of paintwork. Damage caused by the rising damp also frequently manifests itself in the form of biological corrosion, i.e. infestation of the masonry parts with mould, fungal growth, algae, sponge or other microorganisms. The over-acidification of the alkaline building material by rising damp leads to capillary enlargement and thus to porosity, which is associated with increased water transport. The application of *KRICHEX* also acts as stone consolidation.

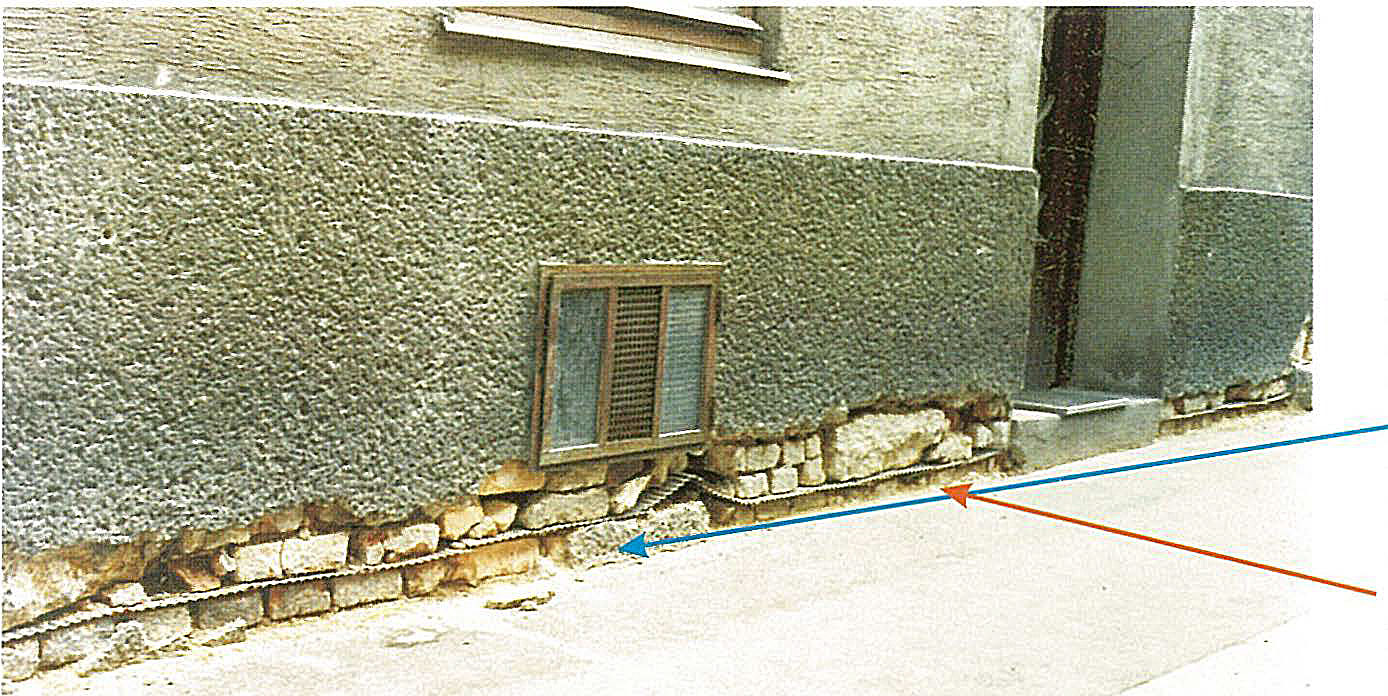

Damage

KRICHEX processing

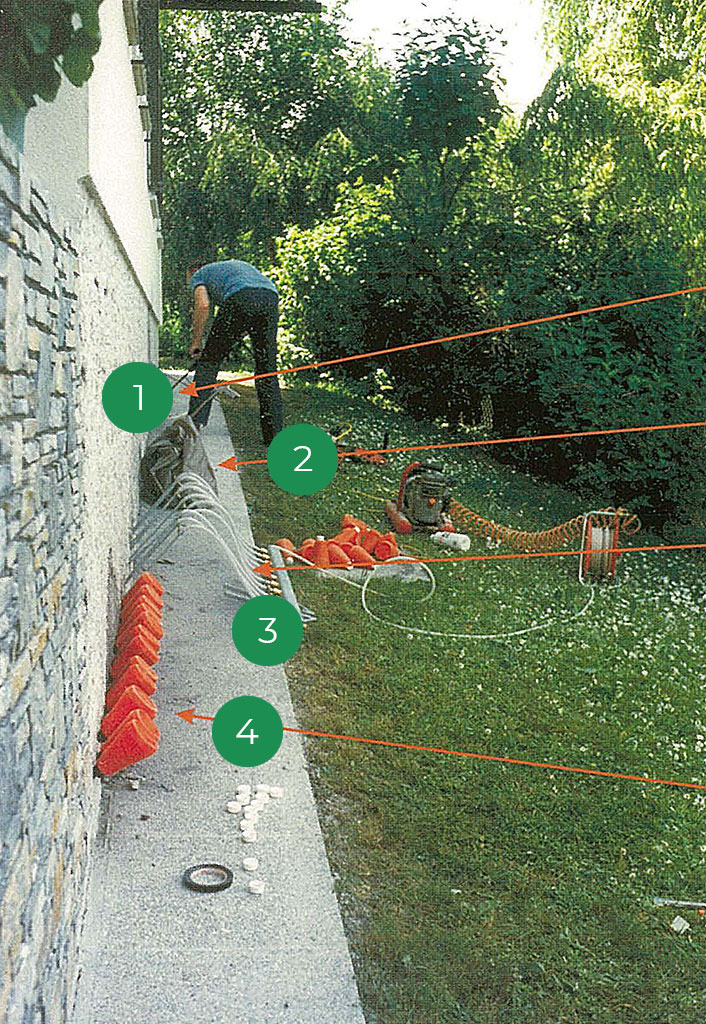

Drilling

Blow out

Ventilate

Put on

Drilling the boreholes

Result of the wall drying carried out

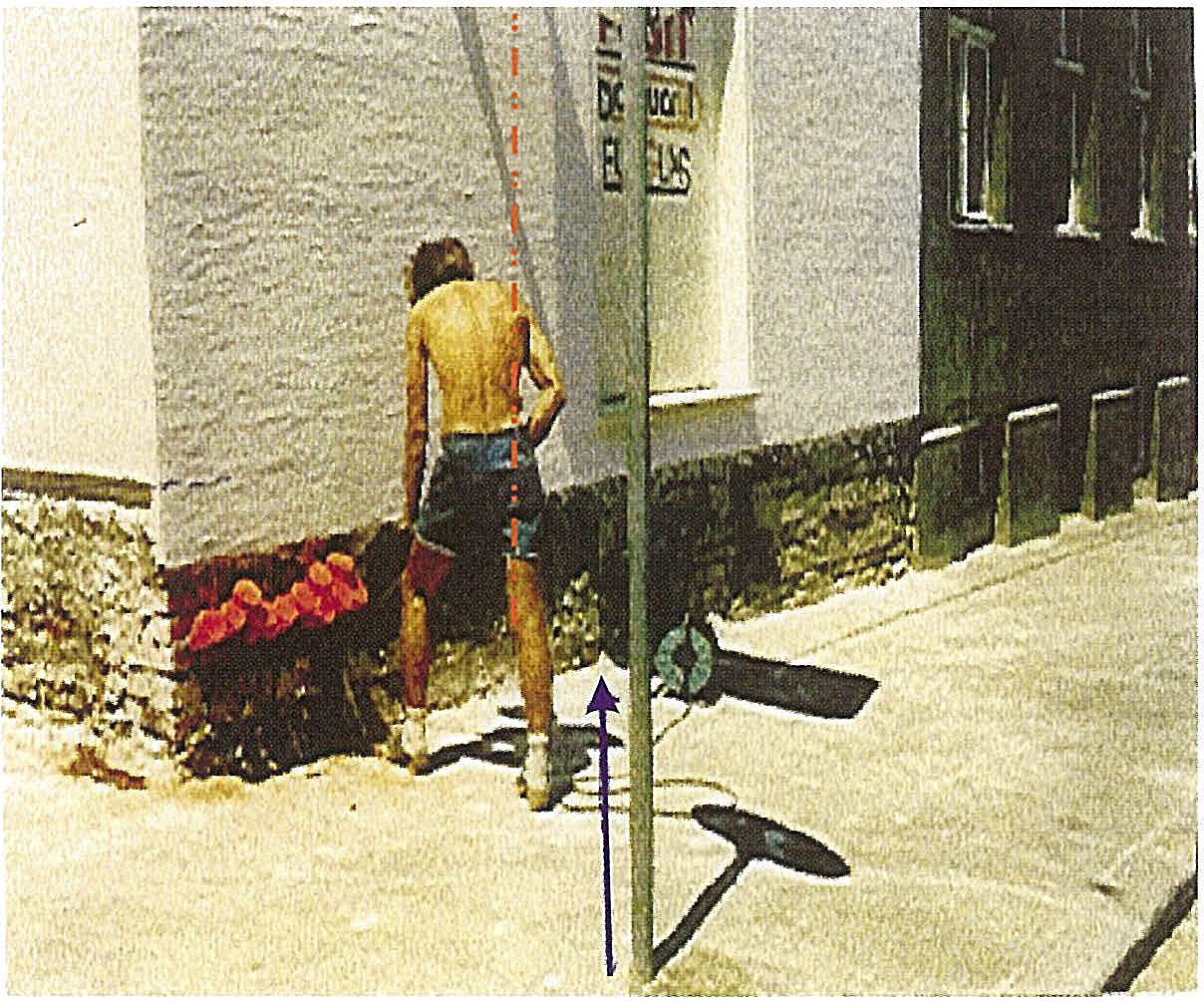

The hammering in of sheets

mechanical system

Remove the plaster and dry out the masonry.

Drying with the help of plaster additives.

Cut-through methods with foil are only possible above ground level.

Drying with the use of a so-called "insulating plaster" or thermal plaster.

Horizontal barriers

- Electro-osmotic systems

a) active

b) passive - Mechanical systems

a) Hammering in steel sheets

b) Cutting through walls and inserting insulating foils etc. - Chemical systems

a) water-soluble silicification

b) Permanently elastic resins (e.g. *KRICHEX*)

In the active version of electroosmosis, an attempt is made to stop or reverse the movement of the water in the masonry by applying an external voltage. For this purpose, electrodes are anchored in the masonry, which are supplied by a power source.

In passive electroosmosis, an attempt is made to build up a galvanic element opposing the field in the masonry in order to counteract the undesired electrophysical support of the water transport. For this purpose, different materials must be used as anode and cathode, which have different normal potentials according to their position in the electro-osmotic voltage series. The resulting voltage should act on the direction of flow of the water in the masonry. All metals in the masonry, such as dowels, fastenings for gutters, lightning conductors, pipes, etc., must be removed or insulated accordingly before installation. (Caution with Cu electrodes and if zinc or galvanised pipes and sheets are present - "electrolysis" = migration of the zinc parts to the CU electrode occurs, consequence: holey pipes or sheets). The electro-osmotic (active and passive) systems are theoretically functional, but in practice it has been shown that they are very susceptible to failure and therefore have a lower success rate.

As far as mechanical systems are concerned, they can only be used to a limited extent (only in brickwork) and the insulation height can only be used above ground or floor level. These systems are also very labour-intensive, involve a lot of dirt and a high risk of structural damage (settlement cracks), and therefore there is a high risk of further damage to the insulation layer. Furthermore, existing pipelines (risers) and reinforcement bars can be destroyed or have to be left out, and no continuous insulation is possible! However, they are effective and functional systems when properly applied.

The systems with the least amount of work (quick processing without static problems) are the chemical ones.

Silicification (water glass solutions) has been known for over 30 years. However, here, as drying progresses, a hardening of the insulating material occurs, the powdery silica (is hygroscopic, i.e. attracts water again) is formed by further water release and the chlorides, nitrates and sulphates present in the rain and groundwater and is then no longer effective as a horizontal barrier. Therefore, water glass solutions (silicification) cannot be expected to provide permanent drainage (temporary solution). Silicification can only be used in slightly damp masonry!

Products proven many times over

for the entire construction industry

Capillary water barrier

More …

Pressure water barrier

More …

Biological wall covering

More …

Infrared heat

Save energy

Website currently under construction